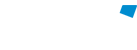

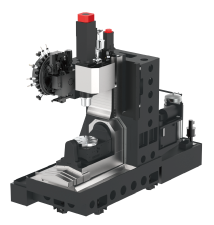

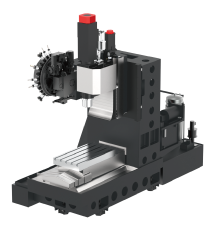

5 AXIS VERTICAL MACHINING CENTER

ADVANCED DESIGN CONCEPT

A New Standard in 5 Axis Machine Performance

A Combination of Intelligence and Practicality

Compact Structure Design

Although the machine width is only 1200mm, its internal working space can reach a diameter of 400mm. This feature not only allows for greater utilization of factory space, but also lowers management costs.

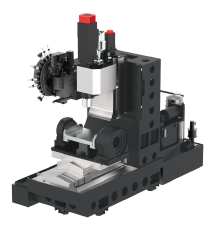

L Type Operation Door

- Whether in manual or automatic workpiece loading/unloading, the operation door provides convenient and spacious working space.

Elegant Appearance Design

- The high quality LED status lights, operation box, and operation door are located at the same level. The modern simplicity and modularity design, in combination with industrial aesthetics and human engineering provide the operator with the optimal machine operating experience.

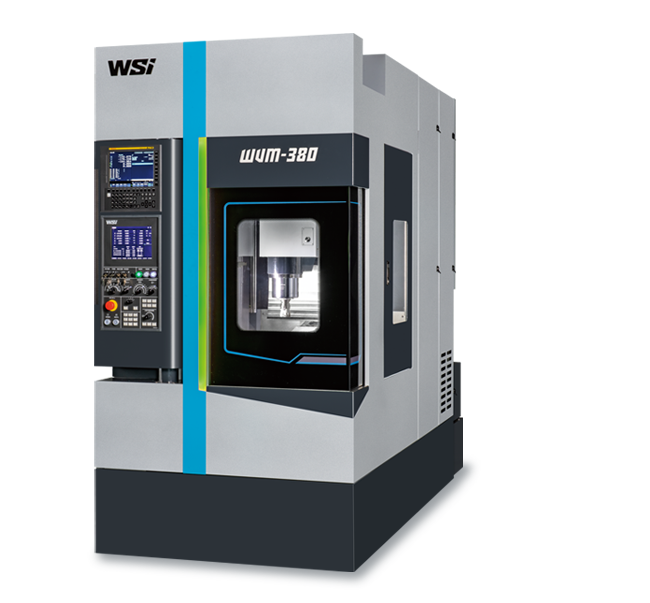

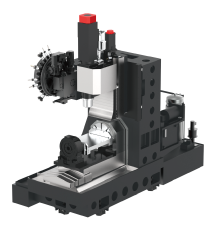

Front-Mount Outside Machine Tool Change

- The tool changer is user-friendly in operation with the use of the magazine operation panel. It does not take up machining time while changing tool, which upgrades the machine utilization rate.

Radial Type Twin-Servo Magazine

- This type of tool magazine can shorten tool change time. It also avoids inertial vibration during tool change, leading to high machining accuracy.

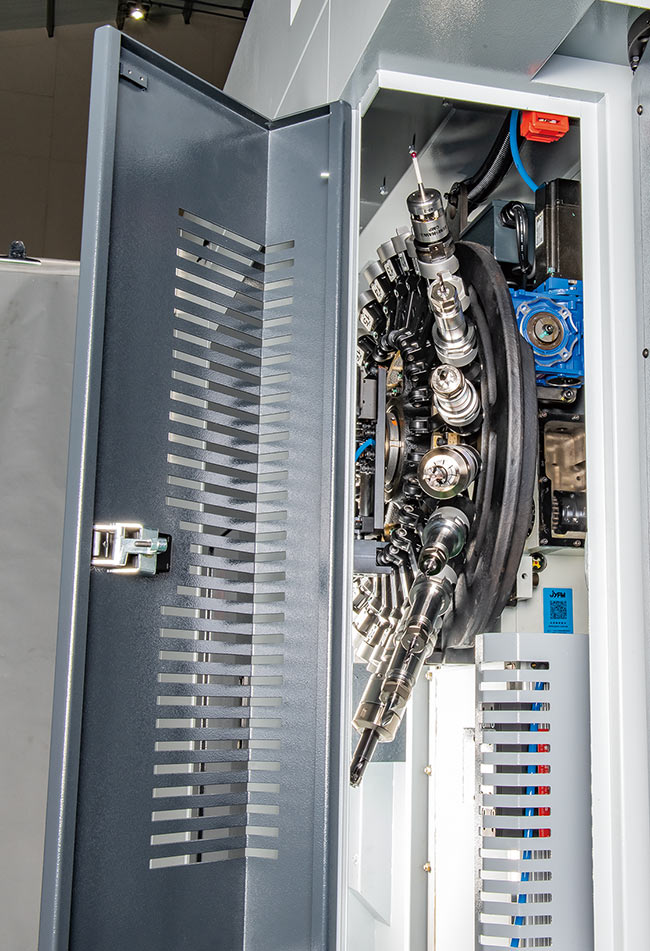

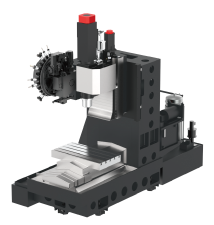

High Accuracy and High Efficiency

- The highly rigid swing type B, C- axes ensure high machining accuracy at any angular position, thus fully meeting the requirements of complicated machining.

- The B and C axes are designed with full circumference hydraulic brake for maximum dependability.

- The worm shaft is a two-section design, allowing backlash to be adjusted by simply turning a simple side of the worm shaft.

Multi-axis Modular Design

B+C axis layout

A-axis layout

B-axis layout

Cross type table

Longitudinal table type

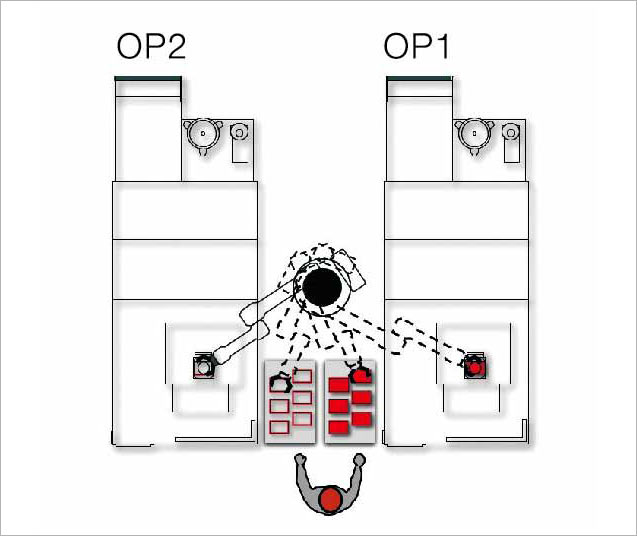

Configuration Application Example

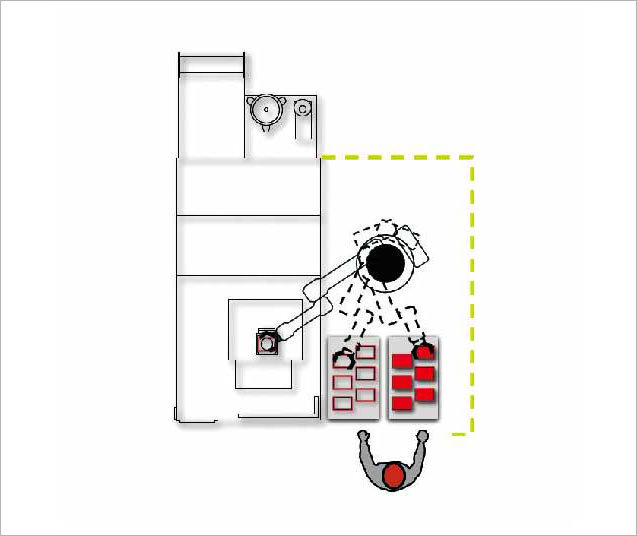

Parts supply by automated part storage

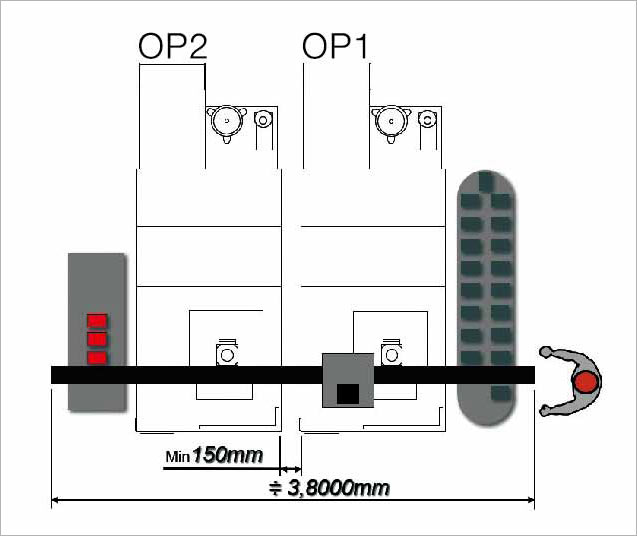

Gantry type parts loader for automated production line

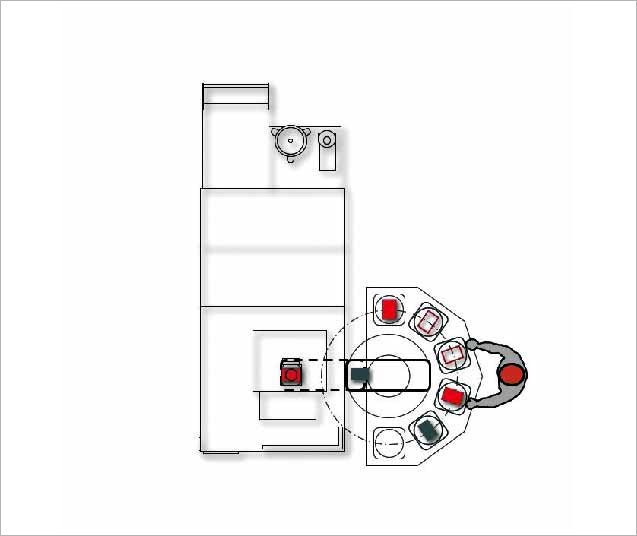

Robot and parts tray for single machine

Robot and parts tray for production line

Machine Specifications:

| MODEL | WVM-380U | WVM-380UK | |

| SPINDLE |

|||

| Spindle nose type | BBT 30 / HSK-E40 | BBT 40 / HSK 63 |

|

| Spindle drive | Direct drive (Built in) | Direct drive (Built in) | |

| Max. spindle speed | 12000 (15000, 20000, 24000, 30000)rpm | 12000 (8000, 20000, 24000)rpm | |

| MOTOR | |||

| MOTOR | 5.5 / 7.5 / 11 / 15 kw | 11/ 15 / 18.5 / 22 kw | |

| TRAVEL | |||

| X/Y/Z | 380 / 400 / 360 mm | 410 / 400 / 455 mm | |

| B/C | -90° ~ +120° / 360° | -90° ~ +120° / 360° | |

| TABLE | |||

| Table size | Ø320 mm | Ø320 mm | |

| Max. swing | Ø400 mm | Ø400 mm | |

| Max. load | Horiz. (kg) | 150 kg | 150 kg |

| Tilt (kg) | 85 kg | 85 kg | |

| TOOL CHANGER | |||

| Number of tools | 24 (32, 40) T | 32 (40, 60) T | |

| Max. tool dia. (w/o adjacent tool) | Ø60 / Ø80 mm | Ø90 (Ø75) / Ø125 mm | |

| Max. tool length | 200 mm | 270 mm | |

| Max. tool weight | 3 kg | 8 kg | |

| OUTLINE DIMENTION | |||

| D x W x H | 2880 x 1200 x 2600 mm | 2880 x 1450(1650) x 2780 mm |

|

| Weight | 4900 kg | 5300 kg | |

● We reserve the rights to change the product specifications, appearance, accessories or advise no longer in use.

Standard Accessories

- Fanuc OiMF plus controller

- Chip conveyor

- Intelligent HMI

- Heat exchanger

- Fully enclosed splashguard

- Automatic lubrication pump

- Work lamp

- Oil fluid separator

Optional Accessories

- High pressure CTS (50/70/105 bar)

- Linear scale

- Oil mist collector

- Workpiece measuring system

- Tool measuring system

- Tool life management system

- Air conditioner for electric cabinet

- Air tight detection for workpiece